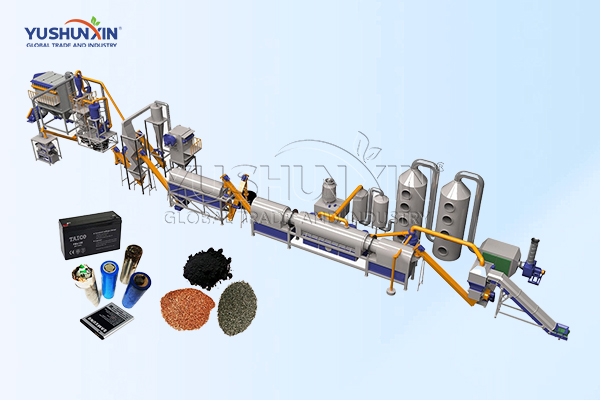

Pyrolytic recycling suits mixed or high-organic-content batteries. You can remove plastics and electrolytes while increasing black powder purity. The process relies on a pyrolysis furnace, vibrating screen, color sorter, and a gas purification system. You will need slightly higher investment and careful environmental monitoring, but the method significantly enhances material quality. You can integrate pyrolysis after mechanical shredding to maximize output and minimize waste. Your staff will also benefit from automated furnace control and fully enclosed material handling systems.

- Home

- About

- Contact

- Products

- LFP Battery Recycling Plant

- Electric Vehicle Battery Recycling Line

- Mobile Phone Lithium Battery Disposal Line

- Lithium Battery Recycling Machine

- 500KG/H Lithium Battery Recycling Plant For Sale

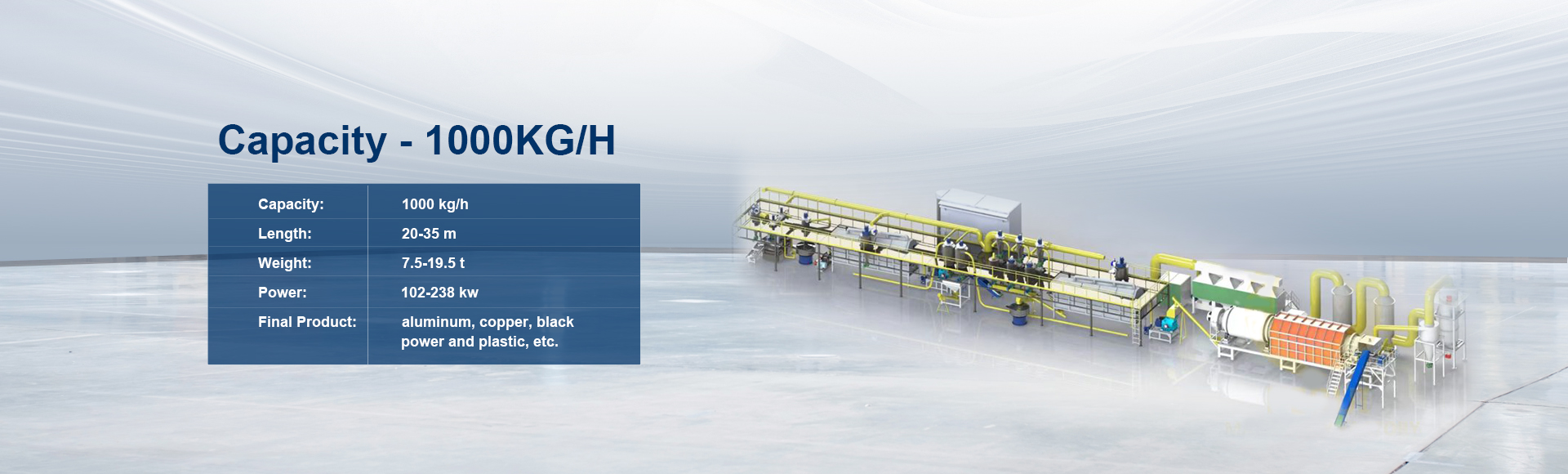

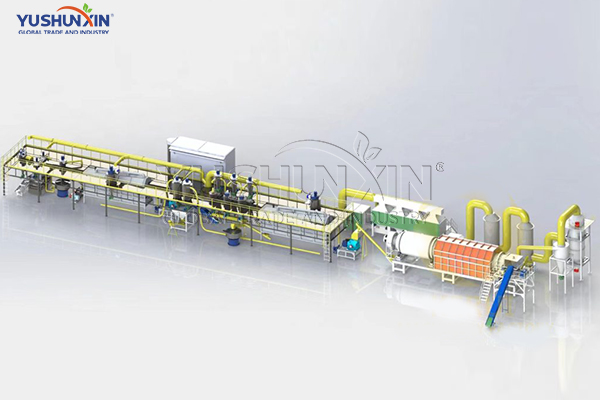

- 1000KG/H Lithium Battery Disposal Project

- Lithium Battery Recycling Machine Cost

- Lithium Battery Discharge Machine

- Lithium Battery Recycling Shredder Machine

- Lithium Battery Recycling Screening Equipment

- Lithium Battery Recycling Dust Collection System

- Solution

- Technology

- Mechanical Lithium Battery Disposal Line

- Lithium Battery Pyrolysis Disposal Process

- Hydrometallurgical Lithium Battery Recycling Plant

- Recycling Solutions for End-of-Life Lithium Battery Separator Materials

- Graphite and Copper Foil Recovery and Reuse in Lithium Battery Disposal

- Black Mass Separation Process in Lithium Battery Disposal

- Eco-Friendly Pollution Control Solution in Lithium Battery Recycling

- Cases&News

- How to Dispose of Lithium Battery in India

- 1000KG/H Lithium Battery Disposal in Japan

- How to Setup a 500KG/H LFP Battery Recycling Plant in Singapore

- $300,000 Cost Mobile Phone Lithium Battery Disposal Plant Building in UK

- How Much is Electric Vehicle Battery Recycling in Australia

- Top 4 Inquires of Lithium Battery Recycling in Singapore

- Mechanical Lithium-ion Battery Recycling Factory Establishing for Fast Investment Return

- Growth of Lithium Battery Disposal Factory Investment in Algeria 2025

- FAQ

Get Solution