- Home

- About

- Contact

- Products

- LFP Battery Recycling Plant

- Electric Vehicle Battery Recycling Line

- Mobile Phone Lithium Battery Disposal Line

- Lithium Battery Recycling Machine

- 500KG/H Lithium Battery Recycling Plant For Sale

- 1000KG/H Lithium Battery Disposal Project

- Lithium Battery Recycling Machine Cost

- Lithium Battery Discharge Machine

- Lithium Battery Recycling Shredder Machine

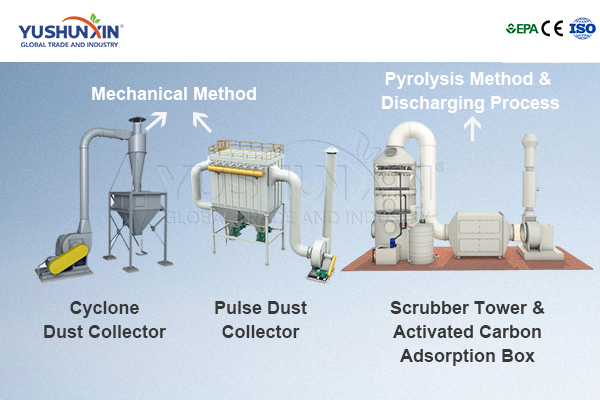

- Lithium Battery Recycling Screening Equipment

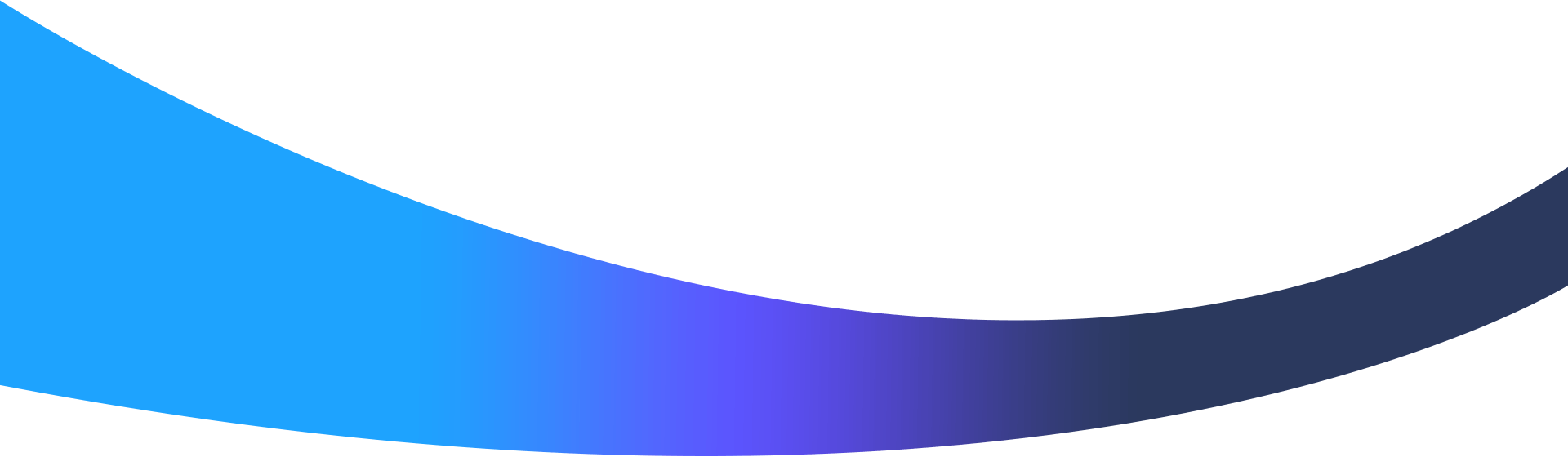

- Lithium Battery Recycling Dust Collection System

- Solution

- Technology

- Mechanical Lithium Battery Disposal Line

- Lithium Battery Pyrolysis Disposal Process

- Hydrometallurgical Lithium Battery Recycling Plant

- Recycling Solutions for End-of-Life Lithium Battery Separator Materials

- Graphite and Copper Foil Recovery and Reuse in Lithium Battery Disposal

- Black Mass Separation Process in Lithium Battery Disposal

- Eco-Friendly Pollution Control Solution in Lithium Battery Recycling

- Cases&News

- How to Dispose of Lithium Battery in India

- 1000KG/H Lithium Battery Disposal in Japan

- How to Setup a 500KG/H LFP Battery Recycling Plant in Singapore

- $300,000 Cost Mobile Phone Lithium Battery Disposal Plant Building in UK

- How Much is Electric Vehicle Battery Recycling in Australia

- Top 4 Inquires of Lithium Battery Recycling in Singapore

- Mechanical Lithium-ion Battery Recycling Factory Establishing for Fast Investment Return

- Growth of Lithium Battery Disposal Factory Investment in Algeria 2025

- FAQ

Get Solution