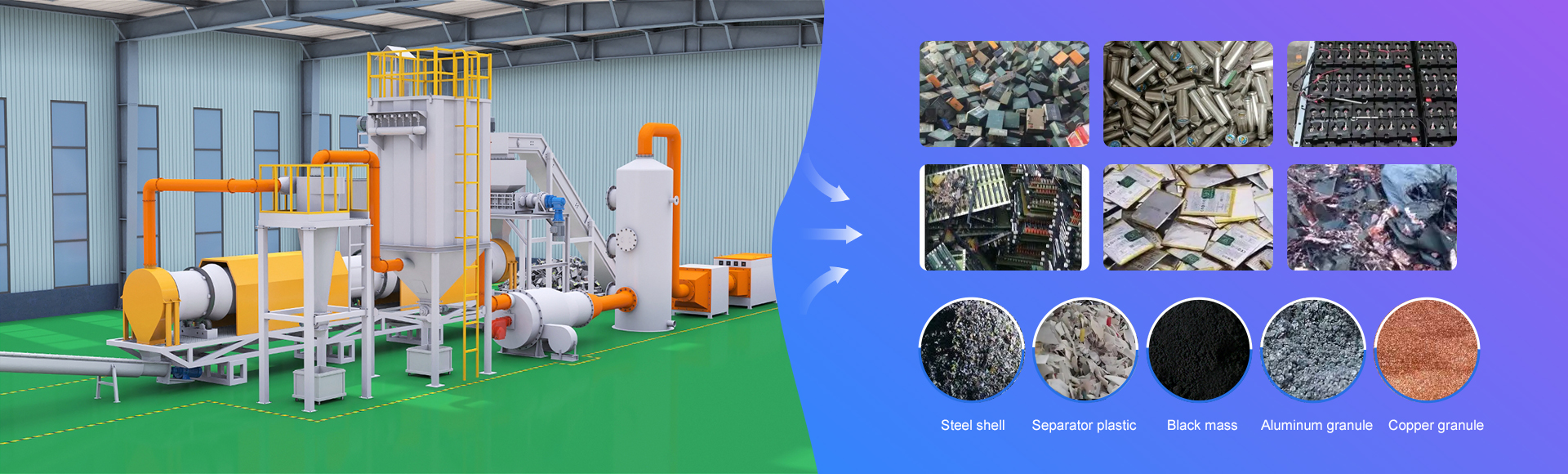

You can equip the line with replaceable crushing blades and variable-speed motors. This configuration ensures you handle hard-shell and soft-shell batteries efficiently. You can adjust blade spacing and rotation speed according to battery type. Consequently, you maintain uniform particle size, which improves downstream separation and overall recovery.

- ផ្ទហ

- អមបី

- ការតាក់តង

- ផលិតផល

- រុក្ខជាតិកែឆ្នៃថ្ម LFP

- ខ្សែបន្ទាត់កែច្នៃអាគុយយានយន្តអគ្គិសនី

- ខ្សែអាគុយថ្មលីចូមចល័តបន្ទាត់

- ម៉ាស៊ីនកែឆ្នៃថ្មលីចូម

- 500រោងចក្រកែឆ្នៃអាគុយ KG / HIHYIL សម្រាប់លក់

- 1000គម្រោងចាក់ថ្នាំបង្ការstrychaធៈ

- តម្លៃម៉ាស៊ីនកែឆ្នៃថ្មលីចូម

- ម៉ាស៊ីនបាញ់ថ្មលីចូម

- ម៉ាស៊ីនថតកាំរស្មីលីចូម

- ឧបករណ៍បញ្ចាំងថ្មលីចូម

- ប្រព័ន្ធប្រមូលអាគុយលីចូម

- ចមលើយ

- បច្ចេកតេស

- ខ្សែអាគុយអាគុយលីចូមមេកានិច

- ដំណើរការនៃការចោលការចោលរបស់ Pyrolys ថ្មរបស់លីចូម

- រោងចក្រកែឆ្នៃថ្មលីចូមេតាឡាមែល

- ដំណោះស្រាយកែឆ្នៃសម្រាប់សំភារៈបំបែកថ្មបញ្ចប់ជីវិត

- ក្រាហ្វិចនិងហ្វ្រេសស្តារការស្តារឡើងវិញហើយប្រើឡើងវិញក្នុងការចោលថ្មលីចូម

- ដំណើរការបំបែកដ៏ធំធេងខ្មៅក្នុងការចោលអាថិនលីចូម

- ដំណោះស្រាយត្រួតពិនិត្យការបំពុលបរិស្ថានដែលងាយស្រួលសម្រាប់អេកូក្នុងការកែច្នៃថ្មលីចូម

- បហ្ចូលយ៉ាង&ប៍តមាន

- តើធ្វើដូចម្តេចដើម្បីបោះចោលថ្មលីចូមនៅប្រទេសឥណ្ឌា

- 1000ការចោលអាគុយ KG / H នៅប្រទេសជប៉ុន

- របៀបតំឡើងរោងចក្រកែឆ្នៃអាគុយ 500 គីឡូក្រាម / ម៉ោង LFP នៅប្រទេសសិង្ហបុរី

- $300,000 ការចំណាយលើទូរស័ព្ទចល័តលីចូមអគាររោងចក្រដើមអាគារ

- តើថាមពលថ្មយានយន្តមានទំហំប៉ុនណានៅអូស្ត្រាលី?

- ឯផ្ទលើ 4 សាកសួរអាគុយលីចូមលីចូមនៅប្រទេសសិង្ហបុរី

- រោងចក្រកែឆ្នៃអាគុយលីស្យូមអ៊ីយ៉ាំដែលបង្កើតឡើងសម្រាប់ការវិនិយោគយ៉ាងឆាប់រហ័ស

- ការលូតលាស់របស់រោងចក្រវិនិយោគរោងចក្រវិនិយោគនៅអាល់ហ្សេរី 2025

- សំណួរគេសួរញឹកញាប់

ទទួលបានដំណោះស្រាយ