Copper foil in lithium batteries is extremely thin but has very high purity. It usually sells for $8,000 to $10,000 per ton in international markets. This demand remains stable because copper foil is essential in many industries beyond batteries, such as electronics and power cables. If you fail to recover copper foil, you lose a valuable revenue source and risk causing environmental damage through metal leaching. Recovering copper foil not only boosts profits but also builds a greener business image.

- ផ្ទហ

- អមបី

- ការតាក់តង

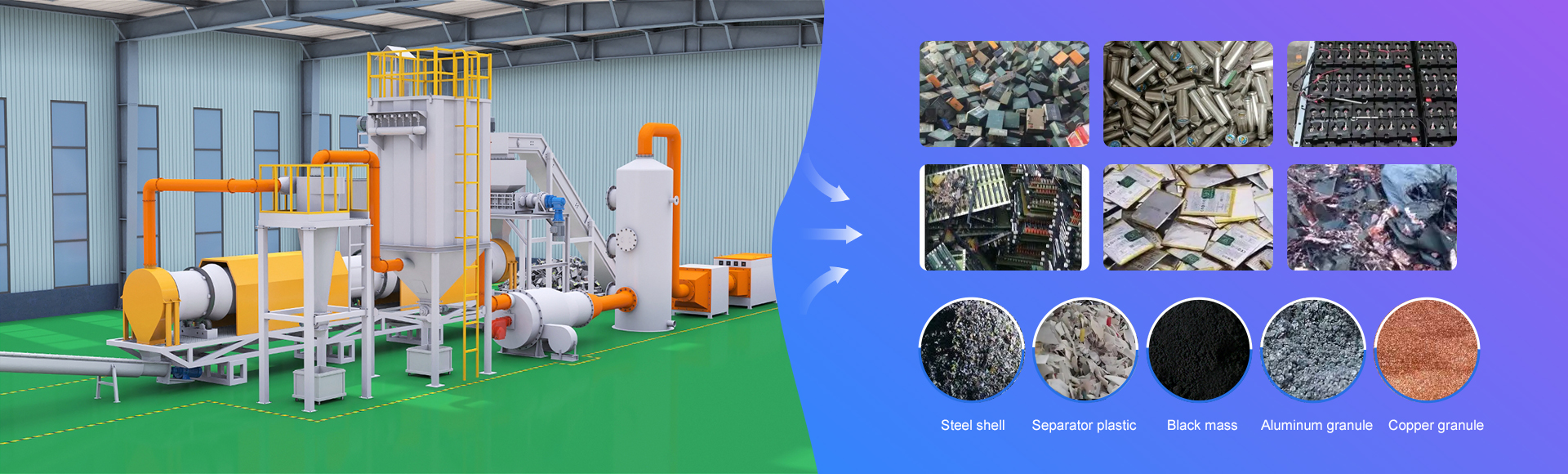

- ផលិតផល

- រុក្ខជាតិកែឆ្នៃថ្ម LFP

- ខ្សែបន្ទាត់កែច្នៃអាគុយយានយន្តអគ្គិសនី

- ខ្សែអាគុយថ្មលីចូមចល័តបន្ទាត់

- ម៉ាស៊ីនកែឆ្នៃថ្មលីចូម

- 500រោងចក្រកែឆ្នៃអាគុយ KG / HIHYIL សម្រាប់លក់

- 1000គម្រោងចាក់ថ្នាំបង្ការstrychaធៈ

- តម្លៃម៉ាស៊ីនកែឆ្នៃថ្មលីចូម

- ម៉ាស៊ីនបាញ់ថ្មលីចូម

- ម៉ាស៊ីនថតកាំរស្មីលីចូម

- ឧបករណ៍បញ្ចាំងថ្មលីចូម

- ប្រព័ន្ធប្រមូលអាគុយលីចូម

- ចមលើយ

- បច្ចេកតេស

- ខ្សែអាគុយអាគុយលីចូមមេកានិច

- ដំណើរការនៃការចោលការចោលរបស់ Pyrolys ថ្មរបស់លីចូម

- រោងចក្រកែឆ្នៃថ្មលីចូមេតាឡាមែល

- ដំណោះស្រាយកែឆ្នៃសម្រាប់សំភារៈបំបែកថ្មបញ្ចប់ជីវិត

- ក្រាហ្វិចនិងហ្វ្រេសស្តារការស្តារឡើងវិញហើយប្រើឡើងវិញក្នុងការចោលថ្មលីចូម

- ដំណើរការបំបែកដ៏ធំធេងខ្មៅក្នុងការចោលអាថិនលីចូម

- ដំណោះស្រាយត្រួតពិនិត្យការបំពុលបរិស្ថានដែលងាយស្រួលសម្រាប់អេកូក្នុងការកែច្នៃថ្មលីចូម

- បហ្ចូលយ៉ាង&ប៍តមាន

- តើធ្វើដូចម្តេចដើម្បីបោះចោលថ្មលីចូមនៅប្រទេសឥណ្ឌា

- 1000ការចោលអាគុយ KG / H នៅប្រទេសជប៉ុន

- របៀបតំឡើងរោងចក្រកែឆ្នៃអាគុយ 500 គីឡូក្រាម / ម៉ោង LFP នៅប្រទេសសិង្ហបុរី

- $300,000 ការចំណាយលើទូរស័ព្ទចល័តលីចូមអគាររោងចក្រដើមអាគារ

- តើថាមពលថ្មយានយន្តមានទំហំប៉ុនណានៅអូស្ត្រាលី?

- ឯផ្ទលើ 4 សាកសួរអាគុយលីចូមលីចូមនៅប្រទេសសិង្ហបុរី

- រោងចក្រកែឆ្នៃអាគុយលីស្យូមអ៊ីយ៉ាំដែលបង្កើតឡើងសម្រាប់ការវិនិយោគយ៉ាងឆាប់រហ័ស

- ការលូតលាស់របស់រោងចក្រវិនិយោគរោងចក្រវិនិយោគនៅអាល់ហ្សេរី 2025

- សំណួរគេសួរញឹកញាប់

ទទួលបានដំណោះស្រាយ