If dust and VOC emissions are not controlled, you increase the risk of water and soil contamination. Heavy metals can remain in the environment for decades, making cleanup extremely costly. Workers exposed to fine particles or harmful vapors may suffer long-term health issues, leading to higher medical costs and potential compensation claims. Communities near your plant may also file complaints if odors or visible dust escape into the surrounding area. These problems can escalate quickly, damaging your brand and reducing trust from both clients and regulators.

- Hem

- Om

- Kontakta

- Produkt

- LFP -batteriåtervinning

- Återvinning av elektriska fordonsbatterier

- Mobiltelefon litiumbatteriavfallslinje

- Litiumbatteriåtervinningsmaskin

- 500Kg/h litiumbatteriåtervinningsanläggning till salu

- 1000Kg/h litiumbatteriavfallsprojekt

- Litiumbatteriåtervinning av maskinkostnad

- Litiumbatteriutsläppsmaskin

- Litiumbatteriåtervinning av rivmaskin

- Litiumbatteriåtervinningsutrustning

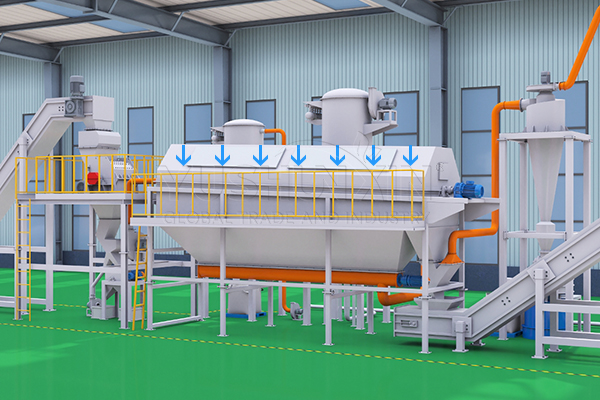

- Litiumbatteriåtervinning av dammuppsamlingssystem

- Lösning

- Teknologi

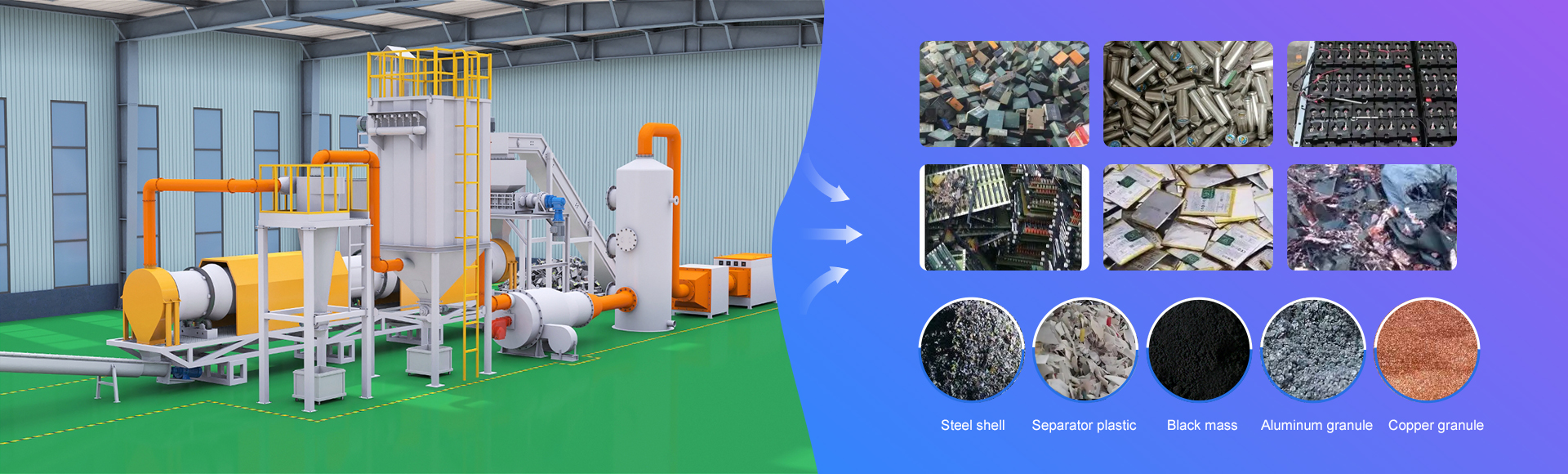

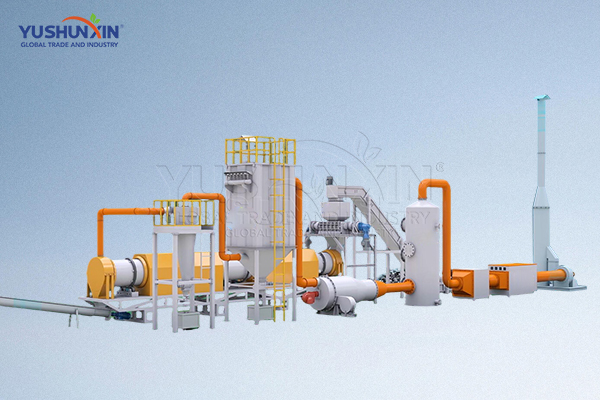

- Mekanisk litiumbatteriavfallslinje

- Litiumbatteripyrolysavfallsprocess

- Hydrometallurgisk litiumbatteriåtervinning

- Återvinningslösningar för LIT-of-LIFE LITIUM-batteriseparatormaterial

- Grafit- och kopparfolieåtervinning och återanvändning vid litiumbatteriavfallshantering

- Svart massavskiljningsprocess i litiumbatteriavfallshantering

- Miljövänlig lösning för föroreningar i litiumbatteriåtervinning

- Fall&Nybörjare

- Hur man kasserar litiumbatteri i Indien

- 1000Kg/h litiumbatteriavfall i Japan

- Hur man ställer in en 500 kg/h LFP -batteriåtervinningsanläggning i Singapore

- $300,000 Kostnad av mobiltelefon litiumbatteriavskaffande växtbyggnad i Storbritannien

- Hur mycket är återvinning av elektriskt fordon i Australien i Australien

- Bästa 4 Förfrågningar om återvinning av litiumbatteri i Singapore

- Mekanisk litiumjonbatteriåtervinning av fabriksupprättande för snabb investeringsavkastning

- Tillväxt av Litium Battery Disposal Factory Investment i Algeriet 2025

- Vanliga frågor

Få lösning