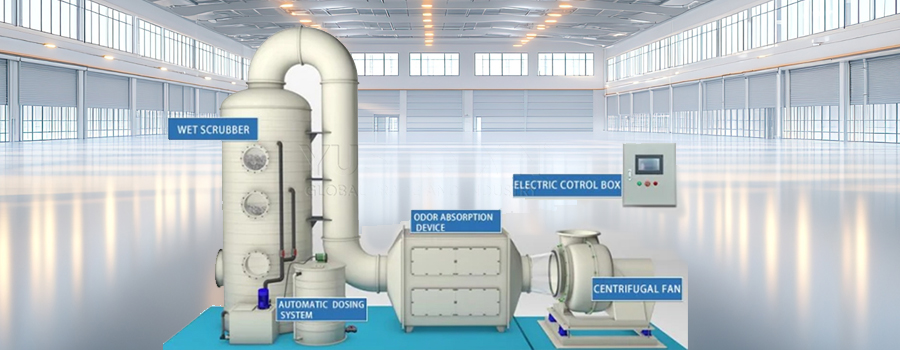

Du bör överväga att installera en pulsdammsugare vid krossnings- och sållningsområdet. Detta system använder högtrycksluftpulser för att rengöra filterpåsarna, säkerställer konsekvent luftflöde och effektiv dammborttagning. Pulsjet-dammsamlaren fångar upp fint damm som genereras när batterier går sönder, förhindrar att den sprids i luften. Som ett resultat, din arbetsyta förblir renare, och du minskar risken för dammexplosioner och andningsproblem för arbetare. Det enkla underhållet och den automatiska rengöringsfunktionen gör pulsstrålesamlare till ett praktiskt val för kontinuerlig drift.

- Hem

- Om

- Kontakta

- Produkt

- LFP -batteriåtervinning

- Återvinning av elektriska fordonsbatterier

- Mobiltelefon litiumbatteriavfallslinje

- Litiumbatteriåtervinningsmaskin

- 500Kg/h litiumbatteriåtervinningsanläggning till salu

- 1000Kg/h litiumbatteriavfallsprojekt

- Litiumbatteriåtervinning av maskinkostnad

- Litiumbatteriutsläppsmaskin

- Litiumbatteriåtervinning av rivmaskin

- Litiumbatteriåtervinningsutrustning

- Litiumbatteriåtervinning av dammuppsamlingssystem

- Lösning

- Teknologi

- Mekanisk litiumbatteriavfallslinje

- Litiumbatteripyrolysavfallsprocess

- Hydrometallurgisk litiumbatteriåtervinning

- Återvinningslösningar för LIT-of-LIFE LITIUM-batteriseparatormaterial

- Grafit- och kopparfolieåtervinning och återanvändning vid litiumbatteriavfallshantering

- Svart massavskiljningsprocess i litiumbatteriavfallshantering

- Miljövänlig lösning för föroreningar i litiumbatteriåtervinning

- Fall&Nybörjare

- Hur man kasserar litiumbatteri i Indien

- 1000Kg/h litiumbatteriavfall i Japan

- Hur man ställer in en 500 kg/h LFP -batteriåtervinningsanläggning i Singapore

- $300,000 Kostnad av mobiltelefon litiumbatteriavskaffande växtbyggnad i Storbritannien

- Hur mycket är återvinning av elektriskt fordon i Australien i Australien

- Bästa 4 Förfrågningar om återvinning av litiumbatteri i Singapore

- Mekanisk litiumjonbatteriåtervinning av fabriksupprättande för snabb investeringsavkastning

- Tillväxt av Litium Battery Disposal Factory Investment i Algeriet 2025

- Vanliga frågor

Få lösning