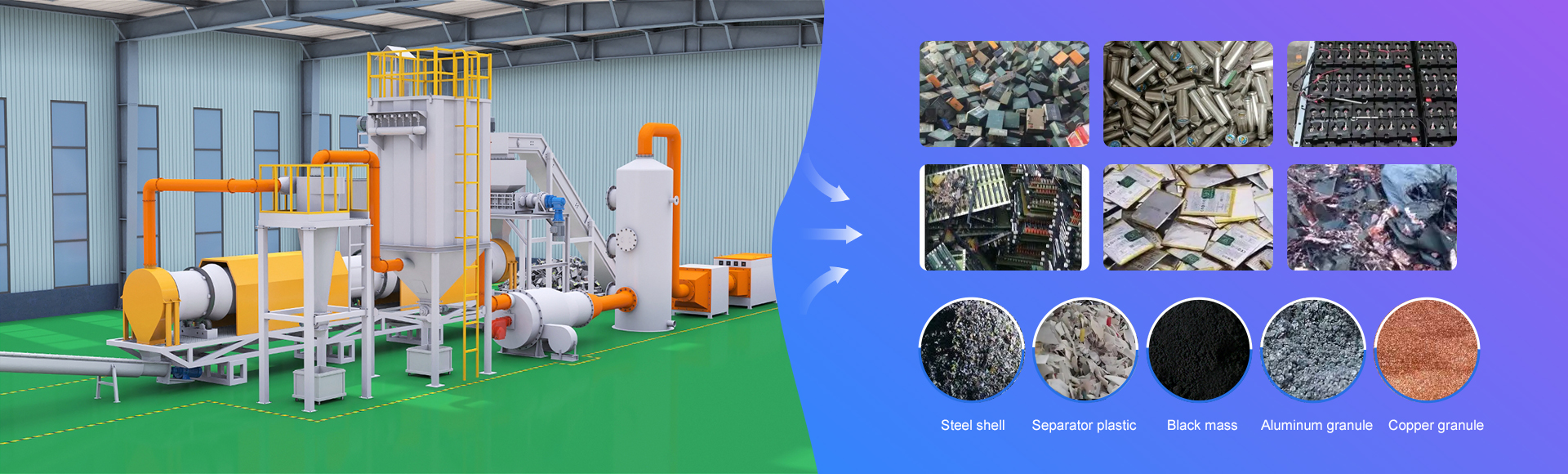

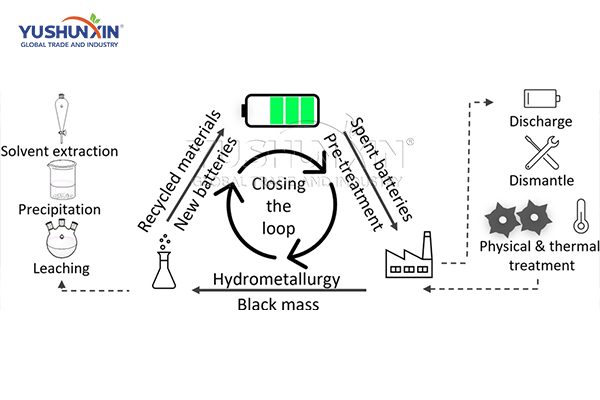

The quality of your input material determines your output. You start with full battery discharge to prevent hazards. Potom, you dismantle and crush the cells. Magnetic and density separation systems remove unwanted metals and plastics. With these steps, you can reach raw material purity above 95% before leaching. High purity reduces reagent waste and improves metal recovery rates. It also ensures that downstream processes run smoothly.

- Domov

- O

- Kontakt

- Výrobky

- Závod na recykláciu batérie LFP

- Recyklácia batérie elektrického vozidla

- Mobilný telefón lítium batérie na likvidáciu

- Recykláciu lítiovej batérie

- 500Závod recyklácie kg/h lítium na predaj

- 1000KG/H LIGHIT BATTERICKÝ PROJEKT

- Náklady na recykláciu lítiovej batérie

- Lítiová vybíjacia batéria

- Stroj na recykláciu lítiovej batérie

- Lítium recyklácie skríningového zariadenia

- Lítium recykláciu systému zberu prachu

- Riešenie

- Technológia

- Mechanická lítiová likvidácia

- Litium batérie Pyrolýza likvidácie

- Hydrometalurgická lítiová recyklácia závodu

- Recyklačné roztoky pre materiály oddeľovača lítium na konci života

- Obnova a opätovné použitie grafitu a medenej fólie pri likvidácii lítiovej batérie

- Proces separácie čiernej hmoty pri likvidácii lítiovej batérie

- Ekologické riešenie riadenia znečistenia pri recyklácii lítiovej batérie

- Prípady&Novinky

- Ako nakladať s lítiovou batériou v Indii

- 1000Kg/h litiná batéria v Japonsku

- Ako nastaviť 500 kg/h LFP recykláciu závodu v Singapure

- $300,000 Náklady na mobilný telefón lítium batérií nakladanie s výstavbou závodu vo Veľkej Británii

- Koľko stojí recyklácia batérie elektrických vozidiel v Austrálii

- Vrchol 4 Dopyty recyklácie lítiovej batérie v Singapure

- Mechanická lítium-iónová továreň na recykláciu batérie

- Rast ligiálnej batérie likvidácie továrne Investície do Alžírska 2025

- Často

Získať riešenie