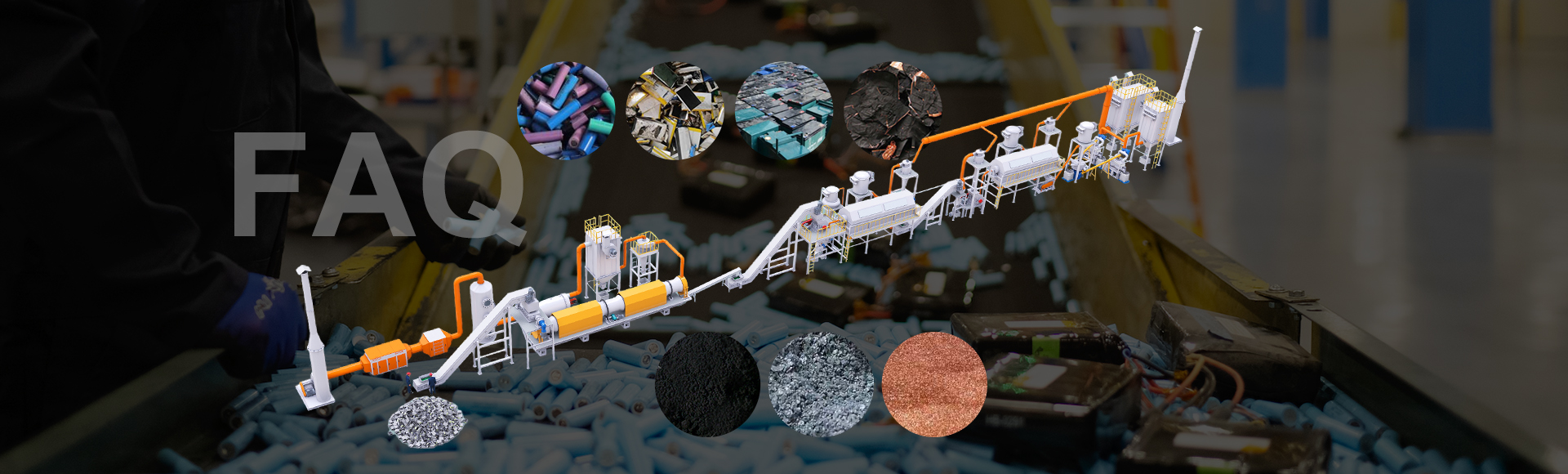

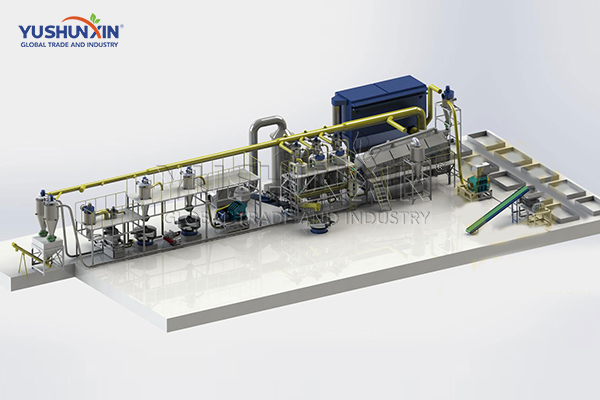

V sekciách drvenia a triedenia, lítiové batérie sa najskôr rozdrvia dvojhriadeľovým drvičom a zmenšia sa pomocou dvoch kladivových mlynov. Materiál potom prechádza cez rotačné a vibračné triediče, magnetický separátor, a gravitačný separátor na oddelenie medi, hliník, železo, plast, a čierny prášok. Usporiadanie strojov v rade a ich tesné zoskupenie vyžaduje približne 50–55 metrov štvorcových, minimalizácia prenosových vzdialeností pri maximalizácii priestorovej efektívnosti.

- Domov

- O

- Kontakt

- Výrobky

- Závod na recykláciu batérie LFP

- Recyklácia batérie elektrického vozidla

- Mobilný telefón lítium batérie na likvidáciu

- Recykláciu lítiovej batérie

- 500Závod recyklácie kg/h lítium na predaj

- 1000KG/H LIGHIT BATTERICKÝ PROJEKT

- Náklady na recykláciu lítiovej batérie

- Lítiová vybíjacia batéria

- Stroj na recykláciu lítiovej batérie

- Lítium recyklácie skríningového zariadenia

- Lítium recykláciu systému zberu prachu

- Riešenie

- Technológia

- Mechanická lítiová likvidácia

- Litium batérie Pyrolýza likvidácie

- Hydrometalurgická lítiová recyklácia závodu

- Recyklačné roztoky pre materiály oddeľovača lítium na konci života

- Obnova a opätovné použitie grafitu a medenej fólie pri likvidácii lítiovej batérie

- Proces separácie čiernej hmoty pri likvidácii lítiovej batérie

- Ekologické riešenie riadenia znečistenia pri recyklácii lítiovej batérie

- Prípady&Novinky

- Ako nakladať s lítiovou batériou v Indii

- 1000Kg/h litiná batéria v Japonsku

- Ako nastaviť 500 kg/h LFP recykláciu závodu v Singapure

- $300,000 Náklady na mobilný telefón lítium batérií nakladanie s výstavbou závodu vo Veľkej Británii

- Koľko stojí recyklácia batérie elektrických vozidiel v Austrálii

- Vrchol 4 Dopyty recyklácie lítiovej batérie v Singapure

- Mechanická lítium-iónová továreň na recykláciu batérie

- Rast ligiálnej batérie likvidácie továrne Investície do Alžírska 2025

- Často

Získať riešenie