Вы можете объединить методы механического и пиролиза для повышения эффективности. Механическая обработка быстро раздается и отделяет металлы, В то время как пиролиз обрабатывает остаточную органику для восстановления дополнительных материалов. Альтернативно, Паража Механическая обработка с влажными гидрометалгургическими методами позволяет уточнить литий, кобальт, и никель с высокой точностью. Использование гибридных методов гарантирует, что вы восстанавливаете максимальное значение, сохраняя при этом операции гладкими и непрерывными.

- Дом

- О

- Контакт

- Продукция

- Завод по переработке батареи LFP

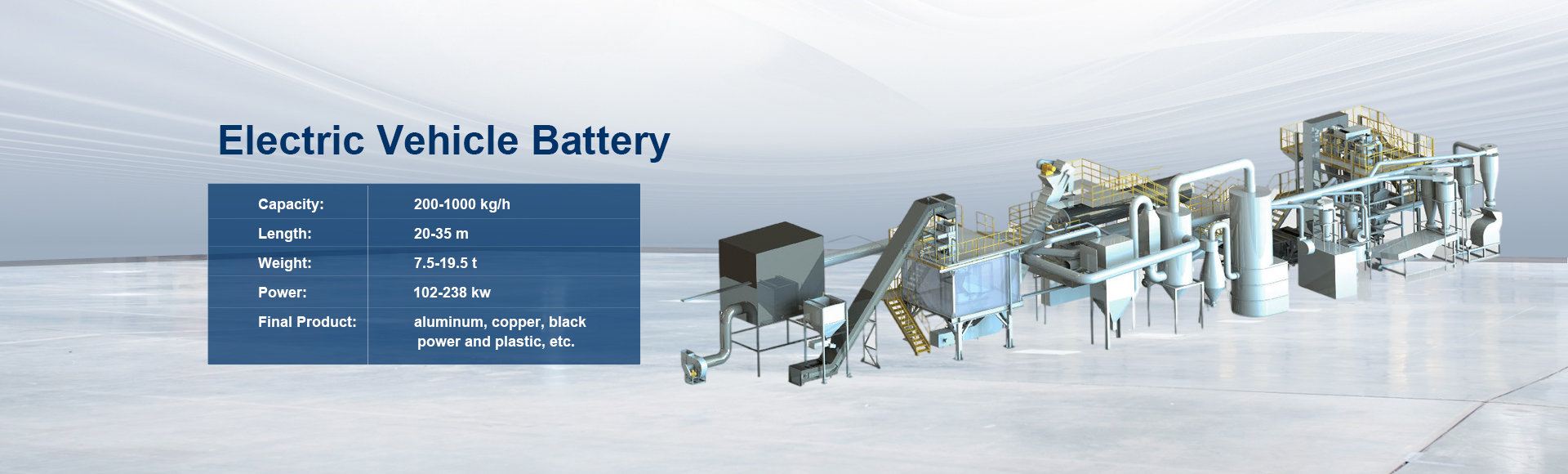

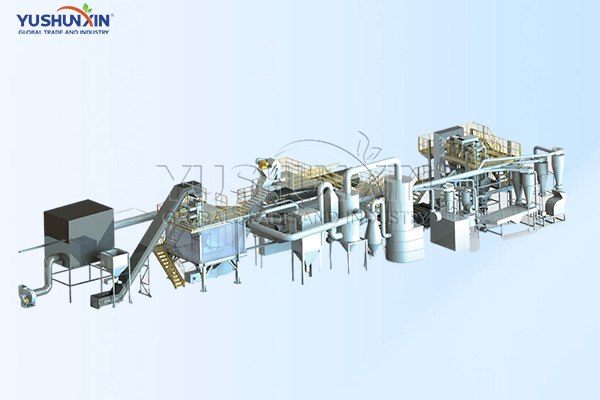

- Линия утилизации аккумулятора электромобилей

- Линия лития мобильного телефона

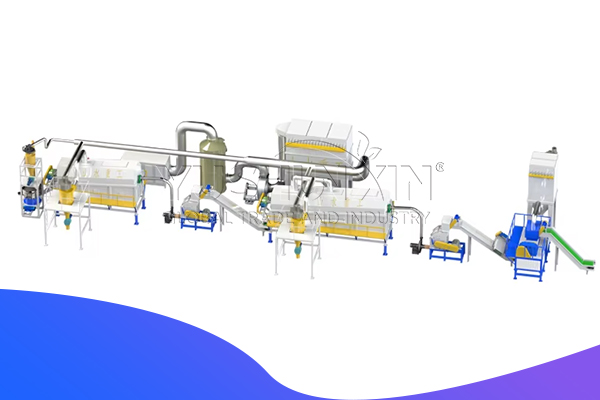

- Машина по переработке лития аккумулятора

- 500Кг/ч литиевые аккумуляторные заводы на продажу

- 1000Кг/ч проект утилизации лития лития

- Стоимость переработки лития утилизации аккумулятора

- Машина разгрузки лития аккумулятора

- Усильница лития утилизации батареи измельчителя

- Оборудование для переработки лития утилизации батареи

- Система сбора пыли литийной батареи

- Решение

- Технология

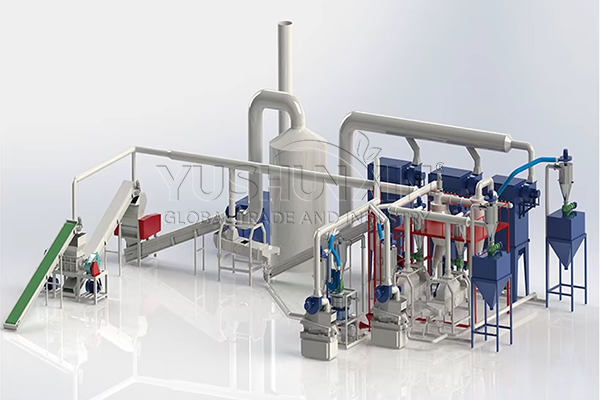

- Лития утилизации механической литиевой батареи

- Процесс утилизации пиролиза лития аккумулятора

- Гидрометаллургическая завод по переработке лития лития

- Решения для утилизации для материалов сепаратора лития лития в конце жизни

- Удаление и повторное использование графита и медной фольги в утилизации литиевых аккумуляторов

- Процесс разделения черной массы в утилизации лития аккумулятора

- Экологичное решение для борьбы с загрязнением при переработке лития аккумулятора

- Случаи&Новости

- Как утилизировать литийную батарею в Индии

- 1000Кг/ч литиеевые батареи в Японии

- Как настроить завод по переработке аккумулятора 500 кг/ч в Сингапуре

- $300,000 Стоимость мобильного телефона Литиевого утилизации завода в Великобритании

- Сколько стоит переработка аккумулятора электромобилей в Австралии

- Вершина 4 Запросы о переработке лития аккумулятора в Сингапуре

- Механическая фабрика по переработке литий-ионных аккумулятор

- Рост инвестиций в утилизацию литий -батареи в Алжире 2025

- Часто задаваемые вопросы

Получите решение