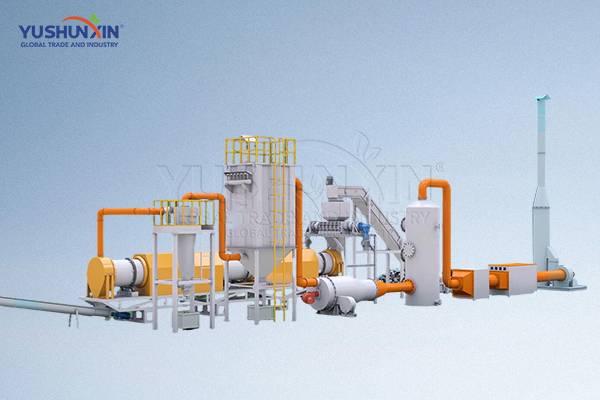

The pyrolysis method requires shredders, high-temperature furnaces, condensation systems, そして dust collection units. And you can thermally decompose organic materials and plastics, while condensation systems recover solvents. それから, dust collection ensures minimal emissions and safe operations. The plant layout requires isolated zones for high-temperature processes to reduce hazards. You can integrate safety systems such as heat insulation and explosion-proof features to protect your team and maintain regulatory compliance.