သင်တစ် ဦး ကိုရွေးချယ်လျှင် 500kg / h lithium Battley Recycling လိုင်း, အလယ်အလတ်ကန ဦး ရင်းနှီးမြှုပ်နှံမှုနှင့်တည်ငြိမ်သောပြန်လည်ရောက်ရှိမှုကိုသင်မျှော်လင့်နိုင်သည်. ထုံးစံအတိုင်း, ထိုကဲ့သို့သောလိုင်းအတွက်စုစုပေါင်းရင်းနှီးမြှုပ်နှံမှုကနေ။ $150,000 သို့ $200,000, သင်၏လိုအပ်သောအလိုအလျောက်နှင့်ဒေသဆိုင်ရာကုန်ကျစရိတ်ပေါ် မူတည်.. ပျမ်းမျှနေ့စဉ်စစ်ဆင်ရေးနှင့်စွန့်ပစ်ပစ္စည်းဘက်ထရီများ၏စဉ်ဆက်မပြတ်ထောက်ပံ့ရေးနှင့်အတူ, သင်ငွေပေးချေမှုကိုအောင်မြင်ရန် 12 သို့ 18 လများ. ဤအချိန်ဘောင်သည်သင့်အားအမြတ်အစွန်းမပြုလုပ်မီပစ္စည်းကုန်ကျစရိတ်များကိုပြန်လည်ရယူရန်ခွင့်ပြုသည်, အထူးသဖြင့်သင်ထိရောက်သောစစ်ဆင်ရေးများနှင့်တည်ငြိမ်ပစ္စည်းများကိုထိန်းသိမ်းထားပါက.

- နေအိမ်

- အကေြာင်း

- တေှ့ဆုံခြင်း

- ထုတ်ကုန်များ

- LFP ဘက်ထရီပြန်လည်သုံးသပ်စက်ရုံ

- လျှပ်စစ်မော်တော်ယာဉ်ဘက်ထရီပြန်လည်အသုံးပြုမှုလိုင်း

- မိုဘိုင်းဖုန်း lithium ဘက်ထရီစွန့်ပစ်ခြင်းလိုင်း

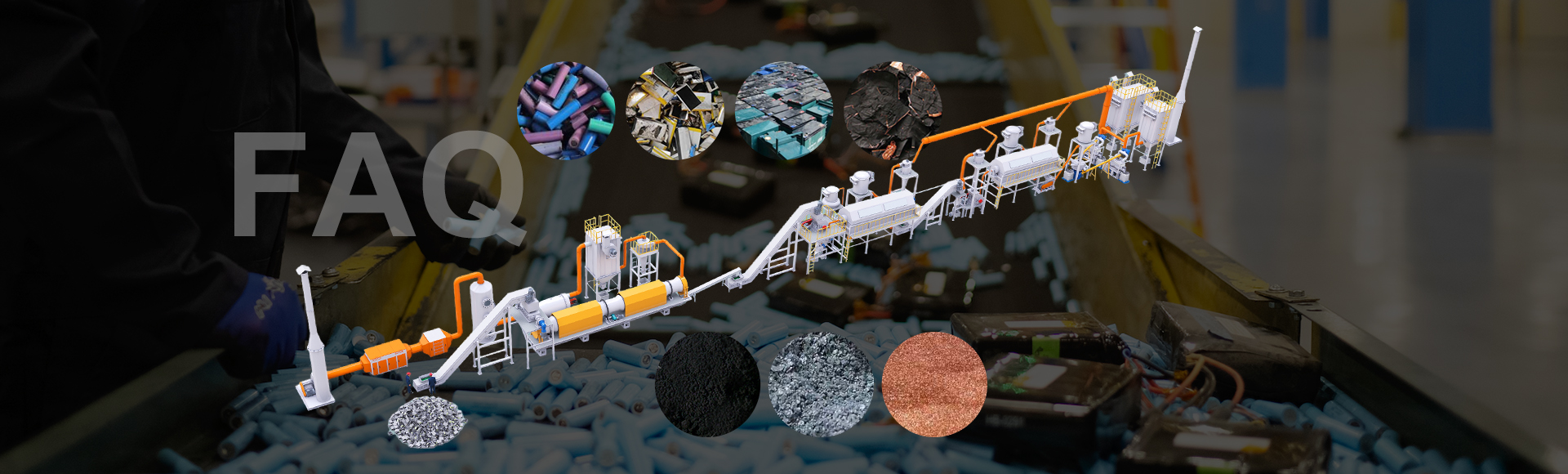

- လီသီယမ်ဘက်ထရီပြန်လည်စက်တင်စက်

- 500KG / H LITHILIAH BALITIAN RETYCLING စက်ရုံရောင်းရန်စက်ရုံ

- 1000kg / H lithium ဘက်ထရီစွန့်ပစ်ခြင်းစီမံကိန်း

- Lithium ဘက်ထရီသည်စက်ကုန်ကျစရိတ်

- လီသီယမ်ဘက်ထရီထုတ်လွှတ်စက်

- lithium ဘက်ထရီ REDYDER စက်

- lithium ဘက်ထရီပြန်လည်စစ်ဆေးရေးကိရိယာများကိုပြန်လည်အသုံးပြုသည်

- လီသီယမ်ဘက်ထရီသည်ဖုန်စုဆောင်းခြင်းစနစ်

- အဖေြ

- စက်မှုလက်မှုလောကဓါတ်ပညာ

- စက်မှုလီသီယမ်ဘက်ထရီစွန့်ပစ်ခြင်းလိုင်း

- လီသီယမ်ဘက်ထရီ Pyrolysis စွန့်ပစ်ခြင်းလုပ်ငန်းစဉ်

- Hydrometallalgicalgicalgical Lithium ဘက်ထရီပြန်လည်အသုံးပြု

- အသက်ဆုံးရှုံးမှုအတွက်ဖြေရှင်းနည်းများကိုပြန်လည်အသုံးပြုခြင်း

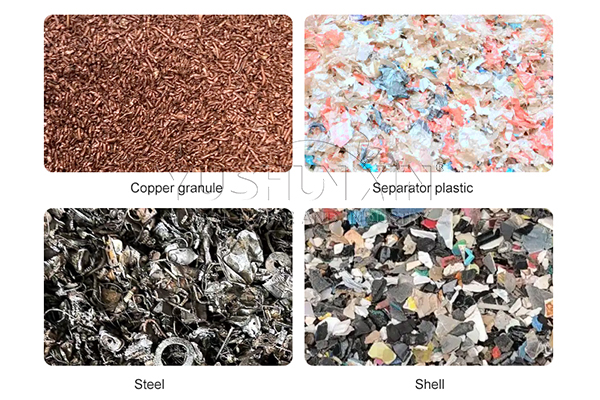

- ဖိုက်နှင့်ကြေးနီသတ္တုပါး Recovery နှင့်လီသီယမ်ဘက်ထရီစွန့်ပစ်ခြင်းတွင်ပြန်လည်အသုံးပြုပါ

- lithium ဘက်ထရီစွန့်ပစ်ခြင်းတွင်အနက်ရောင်အစုလိုက်အပြုံလိုက်ခွဲထုတ်ခြင်းလုပ်ငန်းစဉ်

- ECO-Friendly Poldution Control Integlution Lithium ဘက်ထရီပြန်လည်အသုံးပြုပါ

- ဖြစ်ရပ်များ&သတင်း

- အိန္ဒိယတွင်လီယမ်ဘက်ထရီကိုမည်သို့ဖယ်ရှားရမည်နည်း

- 1000KG / H Lithium ဘက်ထရီကိုဂျပန်နိုင်ငံတွင်ရှိသည်

- စင်္ကာပူရှိ 500kg / H LFP ဘက်ထရီပြန်လည်သုံးသပ်စက်ရုံကိုမည်သို့တပ်ဆင်ရမည်နည်း

- $300,000 ယူကေတွင်မိုဘိုင်းလ်ဖုန်း lithium ဘက်ထရီစက်ရုံတည်ဆောက်ခြင်း

- လျှပ်စစ်မော်တော်ယာဉ်ဘက်ထရီကိုသွစတြေးလျတွင်မည်မျှကျဆင်းသည်

- အထိပ် 4 စင်္ကာပူတွင်လီသီယမ်ဘက်ထရီပြန်လည်အသုံးပြုမှုကိုမေးမြန်းခြင်း

- စက်မှုလီသီယမ် - အိုင်းယွန်းအစာအာဟာရသည်အစာရှောင်ခြင်းပြန်လည်ရင်းနှီးမြှုပ်နှံမှုအတွက်စက်ရုံတည်ဆောက်ခြင်းစက်ရုံတည်ဆောက်ခြင်း

- လီသီယမ်ဘက်ထရီစွန့်ပစ်ခြင်းအယ်လ်ဂျီးရီးယားတွင်စက်ရုံရင်းနှီးမြှုပ်နှံမှု 2025

- အမြဲမေးလေ့ရှိသောမေးခွန်းများ

ဖြေရှင်းချက်ရယူပါ