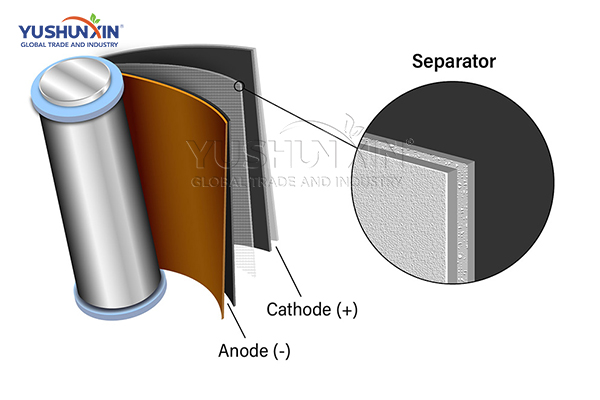

When you recycle separators, their thermal and mechanical properties directly affect your choice of process. Low melting points increase the risk of shrinkage during high-temperature steps. The films are also very thin, often less than 25 micrometers, which makes them prone to static buildup and sticking to other materials. Without proper control, these properties reduce efficiency and increase maintenance time for your equipment.