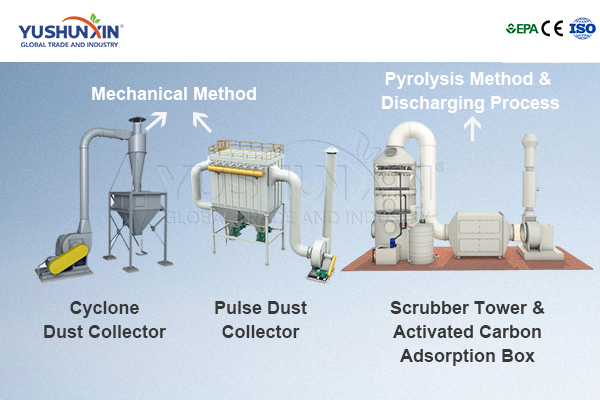

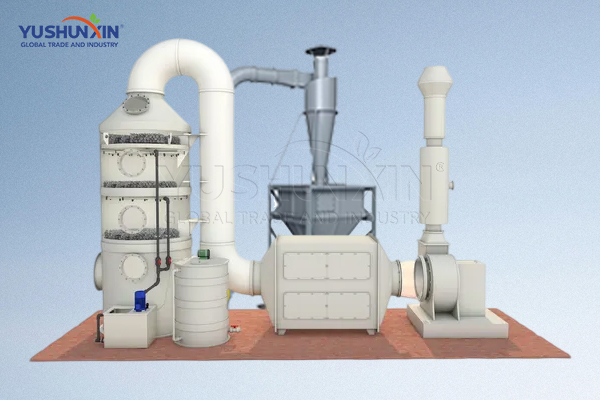

熱分解は、リチウム電池から有価金属や有機化合物を回収するために広く使用されている方法です. しかし, この高温プロセスにより大量の煙が発生します, 揮発性有機化合物, および酸性ガス. スクラバータワーの組み合わせ, 活性炭吸着ボックス, UV光分解ユニットはこれらの汚染物質を効果的に除去します. スクラバーは酸性ミストを低減します, 活性炭は有害ガスを吸着します, 紫外線は揮発性化合物を分解します. この多段階ソリューションを使用する場合, 排出量は制限内にとどまる, 周囲のコミュニティでは臭気や大気汚染が軽減されます。.