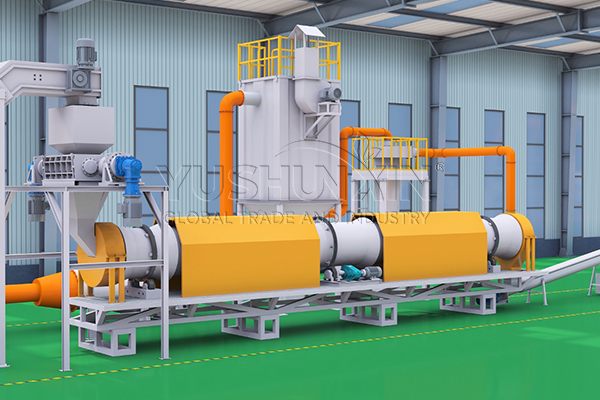

You begin the process by heating the furnace to around 200°C–300°C. This low-temperature pre-treatment stage primarily removes moisture and volatile organic compounds from the batteries. You will find that this step helps prevent steam explosions and reduces the risk of uncontrolled fires. It also softens the external casing and prepares the battery materials for efficient decomposition in later stages.

- Rumah

- Tentang

- Kontak

- Produk

- Pabrik Daur Ulang Baterai LFP

- Jalur Daur Ulang Baterai Kendaraan Listrik

- Saluran Pembuangan Baterai Lithium Ponsel

- Mesin Daur Ulang Baterai Lithium

- 500Pabrik Daur Ulang Baterai Lithium KG/H Dijual

- 1000Proyek Pembuangan Baterai Lithium KG/H

- Biaya Mesin Daur Ulang Baterai Lithium

- Mesin Pelepasan Baterai Lithium

- Mesin Penghancur Daur Ulang Baterai Lithium

- Peralatan Pemeriksaan Daur Ulang Baterai Lithium

- Sistem Pengumpulan Debu Daur Ulang Baterai Lithium

- Larutan

- Teknologi

- Jalur Pembuangan Baterai Lithium Mekanis

- Proses Pembuangan Pirolisis Baterai Lithium

- Pabrik Daur Ulang Baterai Lithium Hidrometalurgi

- Solusi Daur Ulang untuk Bahan Pemisah Baterai Lithium yang Masa Pakainya Sudah Habis

- Pemulihan dan Penggunaan Kembali Grafit dan Tembaga Foil dalam Pembuangan Baterai Lithium

- Proses Pemisahan Massa Hitam dalam Pembuangan Baterai Lithium

- Solusi Pengendalian Polusi Ramah Lingkungan dalam Daur Ulang Baterai Lithium

- Kasus&Berita

- Cara Membuang Baterai Lithium di India

- 1000Pembuangan Baterai Lithium KG/H di Jepang

- Cara Mendirikan Pabrik Daur Ulang Baterai LFP 500KG/Jam di Singapura

- $300,000 Biaya Pembangunan Pabrik Pembuangan Baterai Lithium Ponsel di Inggris

- Berapa Daur Ulang Baterai Kendaraan Listrik di Australia

- Atas 4 Menanyakan tentang Daur Ulang Baterai Lithium di Singapura

- Pabrik Daur Ulang Baterai Lithium-ion Mekanis Dibangun untuk Pengembalian Investasi Cepat

- Pertumbuhan Investasi Pabrik Pembuangan Baterai Lithium di Aljazair 2025

- Pertanyaan Umum

Dapatkan Solusi