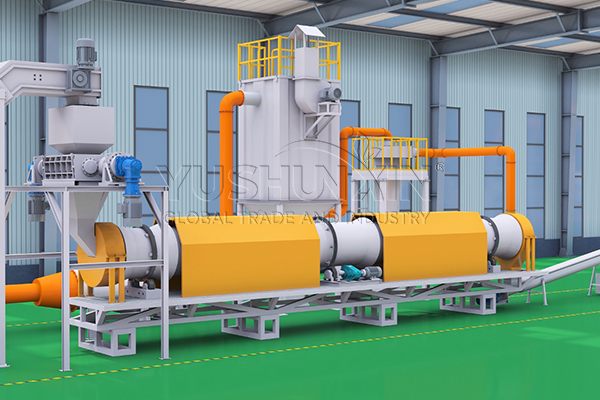

You begin the process by heating the furnace to around 200°C–300°C. This low-temperature pre-treatment stage primarily removes moisture and volatile organic compounds from the batteries. You will find that this step helps prevent steam explosions and reduces the risk of uncontrolled fires. It also softens the external casing and prepares the battery materials for efficient decomposition in later stages.

- Baile

- Maidir

- Teagmháil

- Táirgí

- Gléasra Athchúrsála Ceallraí LFP

- Líne Athchúrsála Ceallraí Feithicle Leictreach

- Líne Diúscartha Battery Litiam Fón Póca

- Meaisín Athchúrsála Battery Litiam

- 500Gléasra Athchúrsála Ceallraí Litiam KG/H Ar Díol

- 1000KG/H Tionscadal Diúscartha Ceallraí Litiam

- Costas Meaisín Athchúrsála Battery Litiam

- Meaisín Scaoilte Battery Litiam

- Meaisín Shredder Athchúrsála Battery Litiam

- Trealamh Scagtha Athchúrsála Battery Litiam

- Córas Bailithe Dust Athchúrsála Battery Litiam

- Réiteach

- Teicneolaíocht

- Líne Diúscartha Battery Litiam Mheicniúil

- Próiseas Diúscartha Pirealaithe Battery Litiam

- Gléasra Athchúrsála Battery Litiam Hydrometallurgical

- Réitigh Athchúrsála d'Ábhair Scartha Ceallraí Litiam Deireadh Saoil

- Aisghabháil agus Athúsáid Scragall Grafite agus Copar i nDiúscairt Battery Litiam

- Próiseas Scaradh Aifreann Dubh i nDiúscairt Battery Litiam

- Réiteach Rialaithe Truaillithe Éicea-Cháirdiúil in Athchúrsáil Battery Litiam

- Cásanna&Nuacht

- Conas Ceallraí Litiam a Dhiúscairt san India

- 1000KG/H Diúscairt Ceallraí Litiam sa tSeapáin

- Conas Gléasra Athchúrsála Ceallraí LFP 500KG/H a Shocrú i Singeapór

- $300,000 Costas Foirgneamh Gléasra Diúscartha Ceallraí Litiam Fón Póca sa RA

- Cé Mhéad atá Athchúrsáil Ceallraí Feithicle Leictreach san Astráil

- Barr 4 Fiosrúcháin faoi Athchúrsáil Battery Litiam i Singeapór

- Monarcha Meicniúla Athchúrsála Ceallraí Litiam-ian ag Bunú le haghaidh Tuairisceán Infheistíochta Mear

- Fás ar Infheistíocht Monarcha Diúscartha Ceallraí Litiam san Ailgéir 2025

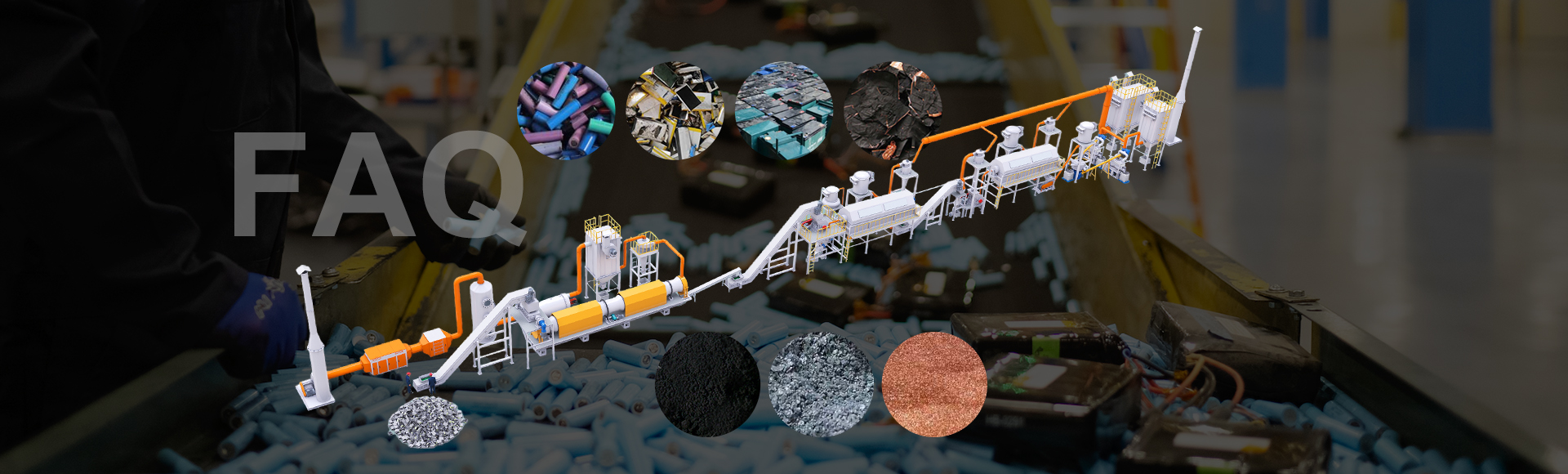

- CCanna

Faigh Réiteach