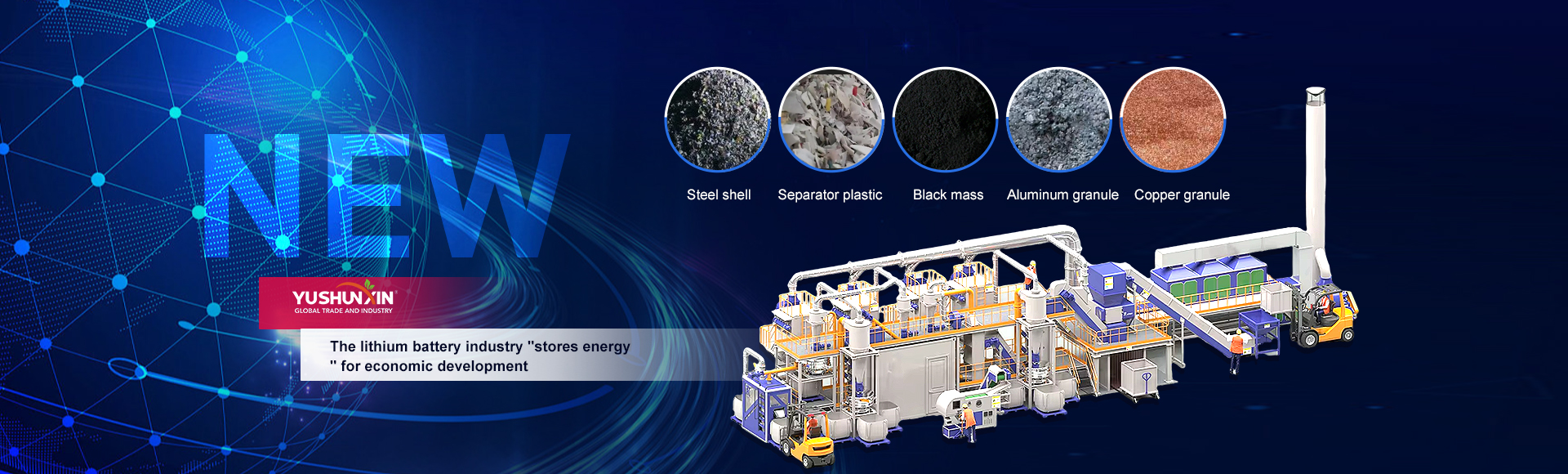

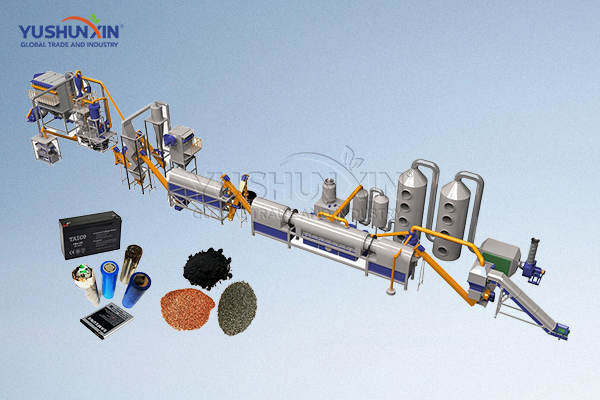

A small-to-medium scale lithium-ion battery recycling plant can be set up starting from $50,000–$80,000, depending on capacity and configuration. The process is simple: battery discharging → double-shaft shredding → hammer mill crushing → dryer→ rotary screener→ magnetic separator→vibrating screening → gravity separation → dust collection. This setup reduces expenses on site area, labor, and electricity, making it an ideal choice for investors who want high output without heavy capital risks. The mechanical battery recycling equipment is easy to maintain, ensuring stable long-term operation.

- Maison

- À propos

- Contact

- Produits

- Usine de recyclage de batteries LFP

- Ligne de recyclage de batteries de véhicules électriques

- Ligne d'élimination des batteries au lithium pour téléphones portables

- Machine de recyclage de batteries au lithium

- 500Usine de recyclage de batteries au lithium KG/H à vendre

- 1000Projet d'élimination des batteries au lithium KG/H

- Coût de la machine de recyclage des batteries au lithium

- Machine de décharge de batterie au lithium

- Machine de déchiquetage de recyclage de batterie au lithium

- Équipement de criblage de recyclage de batteries au lithium

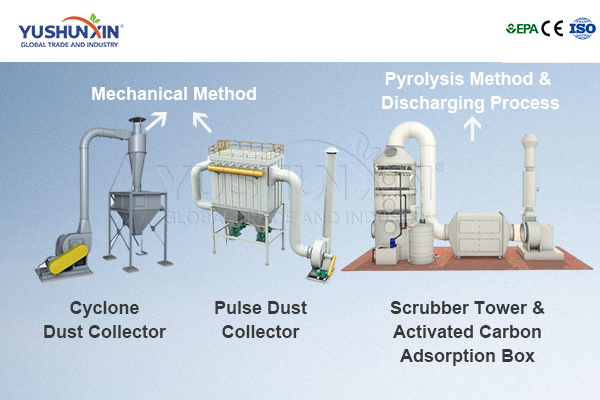

- Système de collecte de poussière de recyclage de batteries au lithium

- Solution

- Technologie

- Ligne d'élimination mécanique des batteries au lithium

- Processus d'élimination de la pyrolyse des batteries au lithium

- Usine de recyclage de batteries au lithium hydrométallurgiques

- Solutions de recyclage pour les matériaux de séparation des batteries au lithium en fin de vie

- Récupération et réutilisation de feuilles de graphite et de cuivre pour l'élimination des batteries au lithium

- Processus de séparation de la masse noire lors de l'élimination des batteries au lithium

- Solution écologique de contrôle de la pollution dans le recyclage des batteries au lithium

- Cas&Nouvelles

- Comment se débarrasser de la batterie au lithium en Inde

- 1000Élimination des batteries au lithium KG/H au Japon

- Comment installer une usine de recyclage de batteries LFP de 500 kg/h à Singapour

- $300,000 Coût de la construction d’une usine d’élimination des batteries au lithium pour téléphones portables au Royaume-Uni

- Combien coûte le recyclage des batteries de véhicules électriques en Australie

- Haut 4 Demandes de renseignements sur le recyclage des batteries au lithium à Singapour

- Création d'une usine de recyclage mécanique de batteries au lithium-ion pour un retour sur investissement rapide

- Croissance des investissements dans les usines d’élimination des batteries au lithium en Algérie 2025

- FAQ

Obtenir la solution