The recycling process begins with a double shafts shredder and two hammer mills, reducing battery pieces from 2–4 cm down to 3 mm. The crushed material then enters a low-temperature dryer at about 120°C, which removes residual electrolyte. Emissions are purified through a dust removal system including a spray tower, activated carbon adsorption, and UV photocatalytic oxidation.

- Kotiin

- Noin

- Ota yhteyttä

- Tuotteet

- LFP-akkujen kierrätyslaitos

- Sähköajoneuvojen akkujen kierrätyslinja

- Matkapuhelimen litiumakkujen hävityslinja

- Litiumparistojen kierrätyskone

- 500KG/H litiumparistojen kierrätyslaitos myytävänä

- 1000KG/H litiumpariston hävitysprojekti

- Litiumparistojen kierrätyskoneen hinta

- Litium-akun purkukone

- Litiumakkujen kierrätyssilppuri

- Litiumparistojen kierrätysseulontalaitteet

- Litiumakkujen kierrätyspölynkeräysjärjestelmä

- Ratkaisu

- Tekniikka

- Mekaaninen litiumakun hävityslinja

- Litiumakun pyrolyysikäsittely

- Hydrometallurgisten litiumakkujen kierrätyslaitos

- Kierrätysratkaisut käyttöiän lopussa olevien litiumakkujen erottimien materiaaleille

- Grafiitti- ja kuparikalvon talteenotto ja uudelleenkäyttö litiumakuntossa

- Musta massan erotusprosessi litium -akun hävittämisessä

- Ympäristöystävällinen pilaantumisenhallintaratkaisu litium-akun kierrätyksessä

- Tapaukset&Uutiset

- Kuinka hävittää litiumakku Intiassa

- 1000Kg/h litium -akun hävittäminen Japanissa

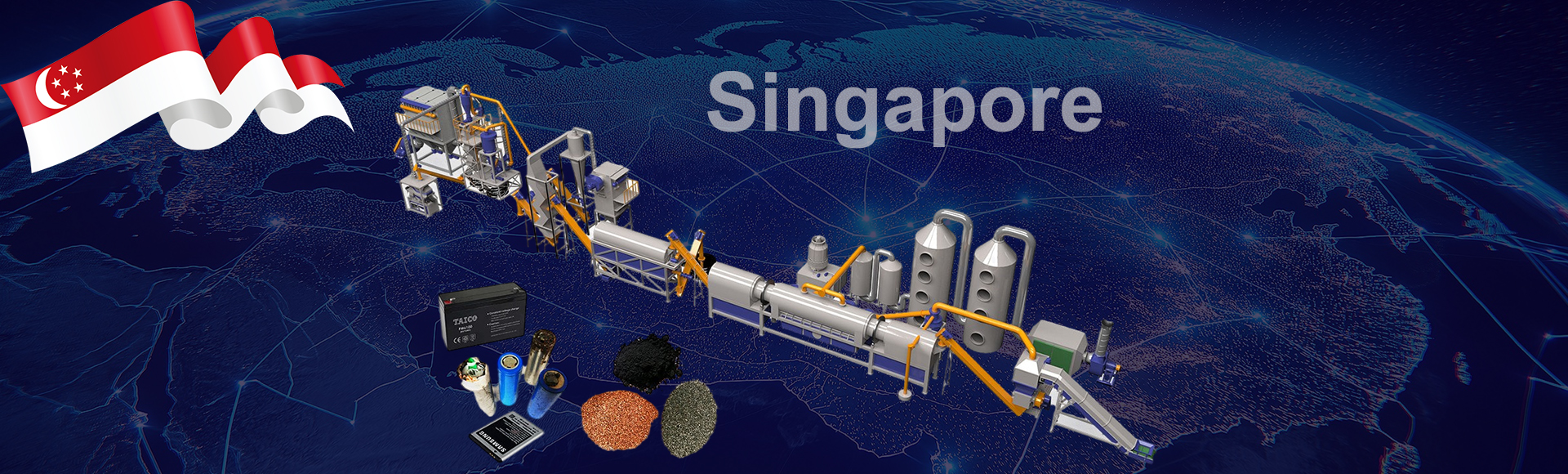

- Kuinka asentaa 500 kg/h LFP -akun kierrätyslaitos Singaporessa

- $300,000 Kustannus matkapuhelimen litium -akun hävittämislaitoksen rakennus Isossa -Britanniassa

- Kuinka paljon sähköautojen akkujen kierrätys Australiassa

- Ylhäältä 4 Tiedustelut litiumparistojen kierrätyksestä Singaporessa

- Mekaaninen litium-ioni-akun kierrätystehdas, joka perustaa nopean sijoituksen tuottoon

- Lithium -akkujen hävittämisen tehdasinvestointien kasvu Algeriaan 2025

- Faq

Saada ratkaisu