Reciclaje mecánico works best for lithium batteries that have clearer structures and fewer additives. You can efficiently process lithium iron phosphate (LFP), nickel manganese cobalt (NMC), and lithium cobalt oxide (LCO) batteries, especially when they come in prismatic or pouch cell formats. You benefit most from using mechanical methods on batteries with simple designs, stable chemistry, and low organic binder content. When batteries are free from heavy contamination or complex polymer layers, you achieve higher yields and lower processing risks.

- Hogar

- Acerca de

- Contacto

- Productos

- Planta de reciclaje de batería LFP

- Línea de reciclaje de baterías de vehículos eléctricos

- Línea de eliminación de baterías de litio de teléfono móvil

- Máquina de reciclaje de batería de litio

- 500Planta de reciclaje de batería de litio kg/h para la venta

- 1000Proyecto de eliminación de baterías de litio kg/h

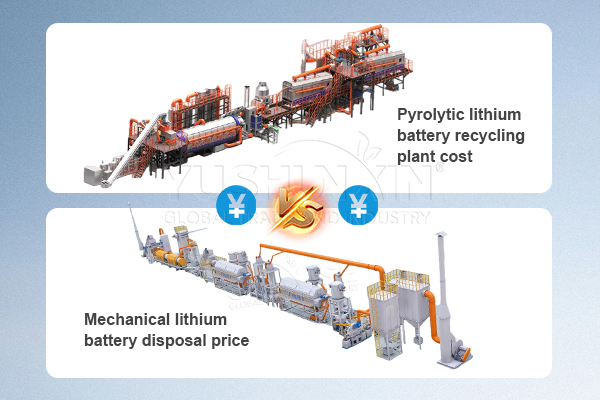

- Costo de la máquina de reciclaje de batería de litio

- Máquina de descarga de batería de litio

- Máquina de reciclaje de batería de litio

- Equipo de detección de reciclaje de baterías de litio

- Sistema de recolección de polvo de reciclaje de baterías de litio

- Solución

- Tecnología

- Línea de eliminación de batería de litio mecánico

- Proceso de eliminación de pirólisis de la batería de litio

- Planta de reciclaje de baterías de litio hidrometalúrgica

- Soluciones de reciclaje para materiales de separador de baterías de litio al final de la vida

- Recuperación y reutilización de aluminio de grafito y cobre en la eliminación de la batería de litio

- Proceso de separación de masa negra en la eliminación de la batería de litio

- Solución de control de contaminación ecológica en reciclaje de baterías de litio

- Casos&Noticias

- Cómo deshacerse de la batería de litio en la India

- 1000Eliminación de la batería de litio kg/h en Japón

- Cómo configurar una planta de reciclaje de baterías LFP de 500 kg/h en Singapur

- $300,000 Costo de la planta de eliminación de baterías de litio de teléfono móvil en el Reino Unido

- ¿Cuánto cuesta el reciclaje de baterías de vehículos eléctricos en Australia?

- Arriba 4 Consulta el reciclaje de baterías de litio en Singapur

- Fábrica mecánica de reciclaje de baterías de iones de litio Establecimiento para retorno de inversión rápida

- Crecimiento de la inversión de fábrica de eliminación de baterías de litio en Argelia 2025

- Preguntas frecuentes

Obtener la solución