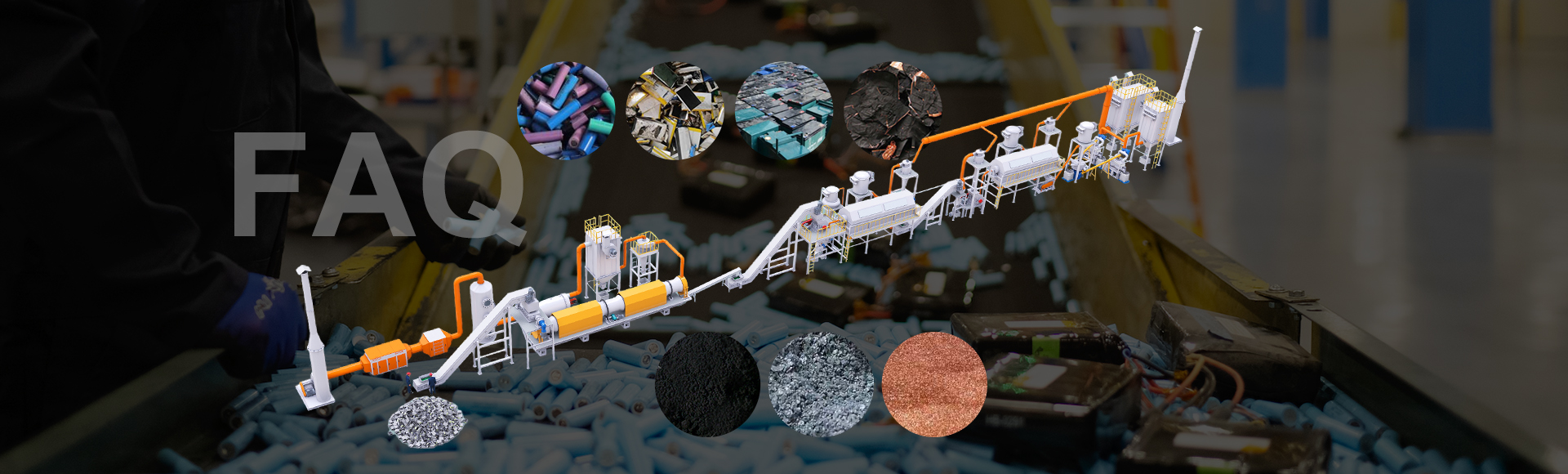

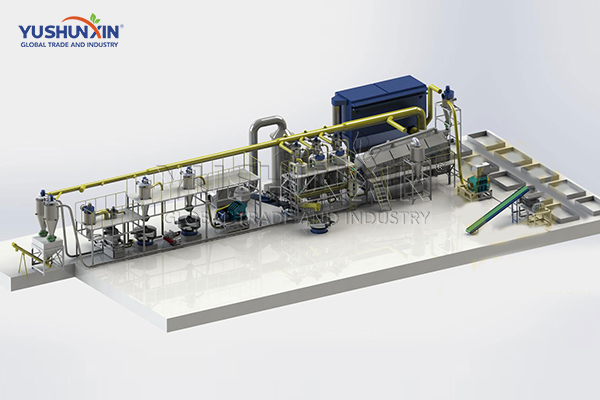

En las secciones de trituración y cribado, Las baterías de litio se trituran primero con una trituradora de doble eje y se reducen de tamaño mediante dos molinos de martillos.. Luego, el material pasa por cribas rotativas y vibratorias., un separador magnético, y un separador por gravedad para separar el cobre, aluminio, hierro, plástico, y polvo negro. Disponer las máquinas en línea y agruparlas estrechamente requiere entre 50 y 55 metros cuadrados., Minimizar las distancias de transferencia y maximizar la eficiencia del espacio..

- Hogar

- Acerca de

- Contacto

- Productos

- Planta de reciclaje de batería LFP

- Línea de reciclaje de baterías de vehículos eléctricos

- Línea de eliminación de baterías de litio de teléfono móvil

- Máquina de reciclaje de batería de litio

- 500Planta de reciclaje de batería de litio kg/h para la venta

- 1000Proyecto de eliminación de baterías de litio kg/h

- Costo de la máquina de reciclaje de batería de litio

- Máquina de descarga de batería de litio

- Máquina de reciclaje de batería de litio

- Equipo de detección de reciclaje de baterías de litio

- Sistema de recolección de polvo de reciclaje de baterías de litio

- Solución

- Tecnología

- Línea de eliminación de batería de litio mecánico

- Proceso de eliminación de pirólisis de la batería de litio

- Planta de reciclaje de baterías de litio hidrometalúrgica

- Soluciones de reciclaje para materiales de separador de baterías de litio al final de la vida

- Recuperación y reutilización de aluminio de grafito y cobre en la eliminación de la batería de litio

- Proceso de separación de masa negra en la eliminación de la batería de litio

- Solución de control de contaminación ecológica en reciclaje de baterías de litio

- Casos&Noticias

- Cómo deshacerse de la batería de litio en la India

- 1000Eliminación de la batería de litio kg/h en Japón

- Cómo configurar una planta de reciclaje de baterías LFP de 500 kg/h en Singapur

- $300,000 Costo de la planta de eliminación de baterías de litio de teléfono móvil en el Reino Unido

- ¿Cuánto cuesta el reciclaje de baterías de vehículos eléctricos en Australia?

- Arriba 4 Consulta el reciclaje de baterías de litio en Singapur

- Fábrica mecánica de reciclaje de baterías de iones de litio Establecimiento para retorno de inversión rápida

- Crecimiento de la inversión de fábrica de eliminación de baterías de litio en Argelia 2025

- Preguntas frecuentes

Obtener la solución