The recycling process begins with a double shafts shredder and two hammer mills, reducing battery pieces from 2–4 cm down to 3 mm. The crushed material then enters a low-temperature dryer at about 120°C, which removes residual electrolyte. Emissions are purified through a dust removal system including a spray tower, activated carbon adsorption, and UV photocatalytic oxidation.

- بيت

- عن

- اتصال

- منتجات

- محطة إعادة تدوير بطارية LFP

- خط إعادة تدوير بطارية السيارة الكهربائية

- خط التخلص من بطارية الليثيوم الهاتف المحمول

- آلة إعادة تدوير بطارية الليثيوم

- 500كيلوغرام/ساعة نبات إعادة تدوير بطارية الليثيوم للبيع

- 1000مشروع التخلص من بطارية الليثيوم كيلوغرام/ساعة

- تكلفة آلة إعادة تدوير بطارية الليثيوم

- آلة تصريف بطارية الليثيوم

- آلة تمزيق بطارية الليثيوم

- معدات فحص بطارية ليثيوم لإعادة تدوير بطارية

- نظام جمع غبار إعادة تدوير بطارية الليثيوم

- حل

- تكنولوجيا

- خط التخلص من بطارية الليثيوم الميكانيكي

- عملية التخلص من الانحلال الحراري بطارية الليثيوم

- نبات إعادة تدوير بطارية الليثيوم الهيدروميتالي

- حلول إعادة التدوير لمواد فاصل بطارية الليثيوم في نهاية العمر

- استعادة غرامات الجرافيت والنحاس وإعادة استخدامها في التخلص من بطارية الليثيوم

- عملية فصل الكتلة السوداء في التخلص من بطارية الليثيوم

- حل التحكم في التلوث الصديق للبيئة في إعادة تدوير بطارية الليثيوم

- حالات&أخبار

- كيفية التخلص من بطارية الليثيوم في الهند

- 1000كيلوغرام/ساعة التخلص من بطارية الليثيوم في اليابان

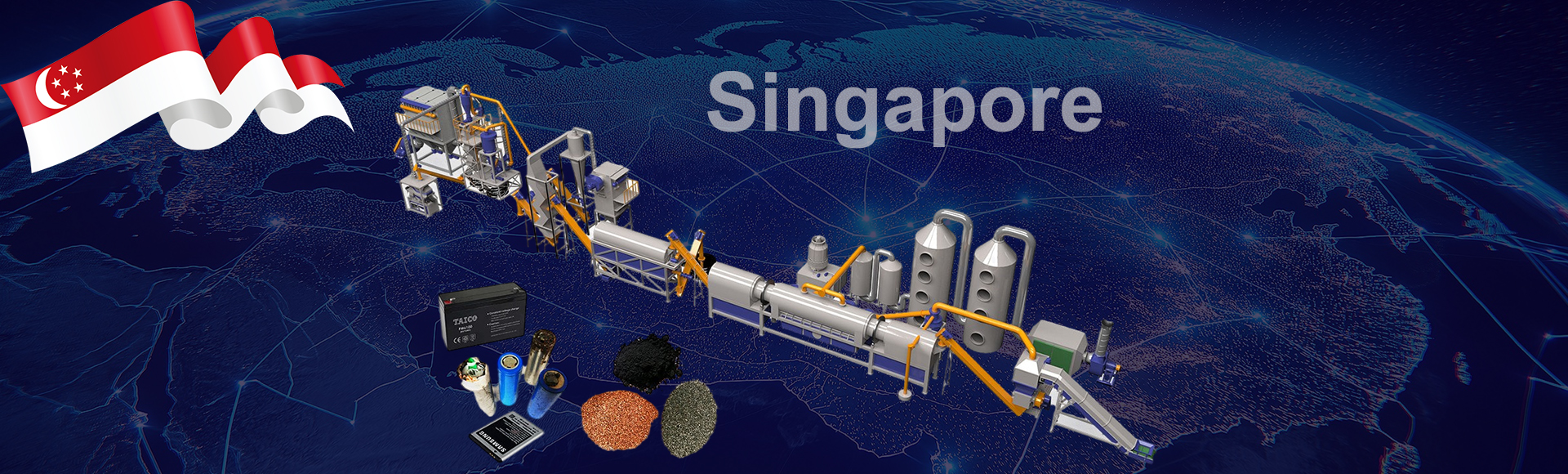

- كيفية إعداد نبات إعادة تدوير بطارية LFP 500 كجم/ساعة في سنغافورة

- $300,000 تكلف الهاتف المحمول مبنى بطارية التخلص من بطارية المبنى في المملكة المتحدة

- كم هي إعادة تدوير بطارية السيارة الكهربائية في أستراليا

- قمة 4 يستفسر عن إعادة تدوير بطارية الليثيوم في سنغافورة

- مصنع لإعادة تدوير بطارية الليثيوم أيون الميكانيكي لإعداد عائد الاستثمار السريع

- نمو استثمار مصنع التخلص من بطارية الليثيوم في الجزائر 2025

- التعليمات

احصل على الحل